The process flow:

Manually put the product -- mesh belt rotation -- spray pre-cleaning -- wind cut isolation -- spray cleaning -- spray pre-rinse -- wind cut isolation -- spray rinse 1-- spray rinse 2-- spray rinse 3-- wind cut 1-- wind cut 2-- heating drying -- manual removal of the product.

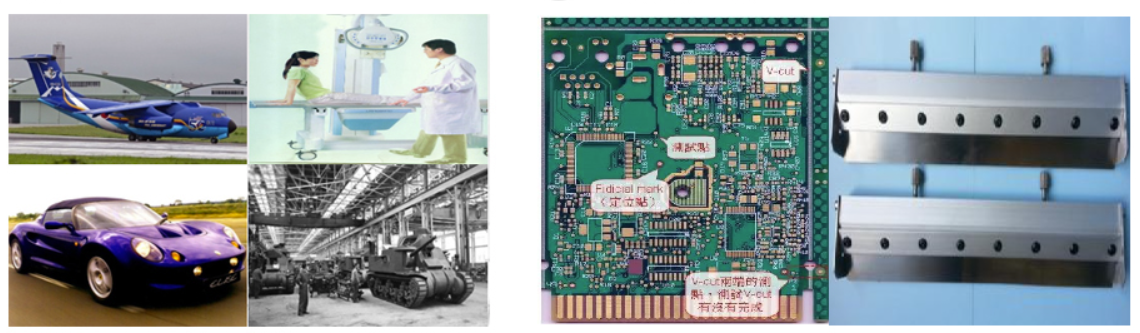

Field of Application:

Pbt-600 on-line PCBA cleaning machine is mainly used for military, aviation, aerospace electronics, medical, automotive new energy, automotive electronics and other coated products and high-end precision products cleaning, a variety of large quantities of PCBA plate cleaning., mainly used in military industry, aviation, aerospace, electronics, medical, automotive products such as new energy, automotive coating and high-end precision cleaning products many varieties, small batch PCBA board cleaning, can effectively clean the SMT/THT PCBA surface after welding residual rosin flux, water-soluble flux, no clean type flux/solder paste and other organic and inorganic contaminants;

• Cleaning solder paste on PCB board with poor printing, cleaning solder paste on scraper, etc.

Equipment features:

• Comprehensive cleaning system: compatible with running water washing or chemical cleaning, for surface residual water soluble flux, solder paste and other organic and inorganic contaminants for thorough and effective cleaning;

• Visualization of the whole process: the cleaning room is equipped with a visual window to make the cleaning process clear;

• Automatic mode: in a cleaning room with spray automatic cleaning, rinsing, drying the whole process;

• Scientific nozzle design (patent) : left and right incremental distribution, improve cleaning efficiency, up and down dislocation distribution, completely solve the cleaning blind area;

• Adjustable nozzle design: it solves the problem of collision and splashing of small size PCBA under high pressure spray during cleaning;

• Tank heating system: greatly improve the cleaning efficiency, shorten the cleaning time, enhance the cleaning efficiency;

• Equipment preparation and body material: 3 channels of cleaning + 4 channels of rinsing + water cutting with air knife + ultra-long infrared hot air circulation drying section;

• Overall 304 stainless steel body, acid, alkaline and other cleaning fluid resistance.

Technical parameters:

Within the capacity | And the number |

Installation dimensions | 5500mm(L)×1550(W)×1620mm(H) |

capacity | According to: 450mm×100mm plate, 1 "plate spacing, 0.3-0.4 m/min working speed, output in: about 15m2/ hour |

Workpiece size | Maximum: 450mm(W)×100mm(H) L=∞(fixture fixed) Minimum: 50mm×50mm thickness: 0.1-4mm Maximum width: 450 Unlimited length |

In her work | 0.1 1.5 m/min is adjustable; The recommended setting is 0.3-0.4m/min |

Conveying surface height | 950mm |

Conveying surface width | 450mm |

Direction of access plate | Left in and right out (viewed from the front window of the unit) |

Exhaust (pumping air volume) | About 36 m3 / Min |

Equipment net weight | ≈2000KG |

The power supply requirements | AC380 3P 50Hz rated power: 60KW rated current: 95A |