Process flow:

Manual placement - disk 360 degree rotation - pressurized spray centralized filtration cleaning - recycling cleaning liquid - pressurized spray centralized filtration rinsing - air cut drying - automatic door down manual removal.

Field of Application:

Ptb-700s rotary spray cleaning machine fully automatic cleaning, rinsing, drying process, and cleaning process visualization; Using UNIQUE eight spray arm cleaning, rinsing design, three air knife air drying design, cleaning, rinsing using online filtration, to ensure cleanliness.

Used in: SMT, DIP fixture cleaning, scraper, condenser cleaning, all kinds of workpiece surface cleaning, all kinds of hardware parts after machining cleaning, equipment after disassembly parts cleaning, auto parts, all kinds of shell, box and other surface residual pollutants hole wall.

Condenser class Fixture class Hardware class Printing scraper class

Equipment features:

• 1M diameter disk cleaning mode: When the equipment is in operation, the workpiece rotates with the cleaning basket, and at the same time, the spraying system sprays the heated cleaning liquid at high pressure, so that the workpiece can be obtained in all directions

To automatic cleaning, rinsing, drying the whole process;

• Visualization of the whole process: visual window and LED light device make the cleaning process clear at a glance;

• The most scientific nozzle design: upper, lower and side distribution, completely solve the cleaning blind area, the upper spray arm can be highly adjustable;

• The nozzle pressure can be adjusted: to solve the size of the workpiece in the cleaning spray conditions of collision, splashing problem;

• The fire grating is installed in the exit and entry window to protect personal safety, and the toughened glass door runs up and down automatically;

• Diluent tank/rinse tank with heating system compatible with running water washing or chemical cleaning;

• Body material: stainless steel body, acid, alkaline and other cleaning fluid resistance.

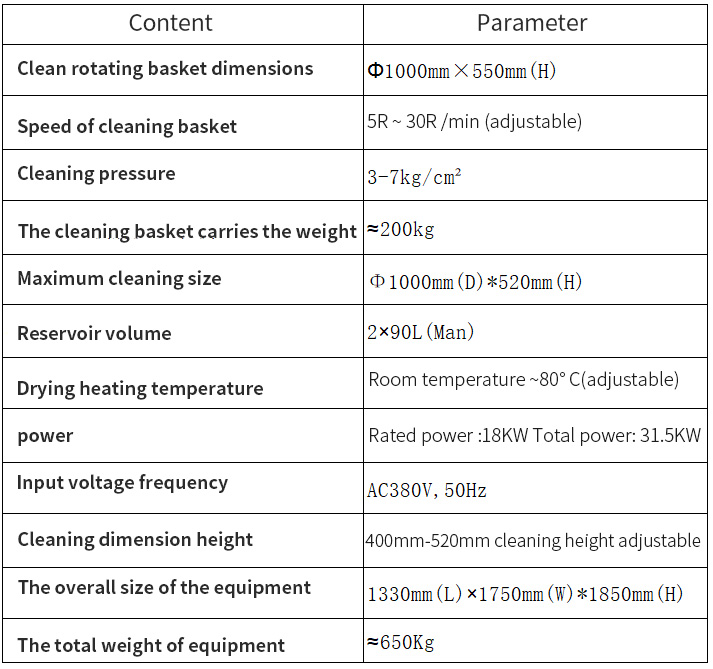

Technical parameters: